23 Jan Nova-Institute releases list of European biocomposite producers

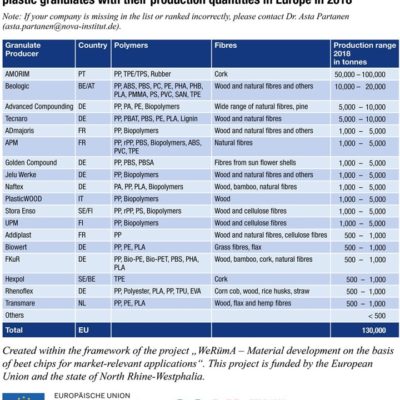

According to the report, there are 30 producers of biocomposite granules producing almost 130,000 tons of sustainable materials.

Nova-Institute (Hürth, Germany) has published a list of all European producers and suppliers of biocomposite granulates, including 30 producers from nine countries. The amount of granulates produced and sold in 2018 was almost 130,000 tons, which Nova-Institute says is a considerable increase compared to previous years and expected to grow substantially again in the next few years.

According to the report, the Portuguese cork manufacturer Amorim is the largest European producer of biocomposite granulates, producing more than 50,000 tons per year. Amorim’s cork materials are used in products such as shoes, handles for sports equipment or bathroom floors. Biologic (Zwevegem, Belgium) produces more than 10,000 tons per year, and Advanced Compounding (Rudolstadt, Germany) and Tecnaro (Ilsfeld, Germany) produce more than 5,000 tons per year each. These three companies offer a wide range of polymers as well as a wide variety of wood and natural fibers as fillers and reinforcers.

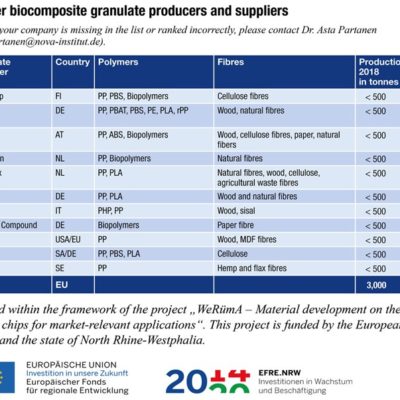

Nova-Institute reports that large companies that produce wood-based products and pulp, such as UPM (Finland), Sappi (South Africa) and Stora Enso (Sweden/Finland), have also entered into the production of biocomposites. The two tables above and below give a comprehensive overview of the 30 biocomposite granulate manufacturers in Europe.

According to the report, cork granulates account for the largest share of biocomposite granulates produced, at approximately 60%. Wood and cellulose fiber granulates account for slightly more than 25% and natural fiber granulates for 15%.

According to Nova-Institute, today’s customers expect companies to reduce plastics in their products, and biocomposites can be a solution that replaces plastic without compromising performance and processability. Nova-Institute says 30-80% of plastic fillers are being replaced for biogenic fillers such as wood flour or cook, or natural fiber reinforcement. These more natural, biocomposite granulates can be processed on existing machines without major modifications, whether by injection molding, extrusion or additive manufacturing/3D printing. Biocomposite products are also said to offer different mechanical properties, making the products they are added to stiffer, more tensile and bend-resistant due to the natural fibers.

Nova-Institute says a rise in biocomposites use has occurred in part because larger quantities of high-quality granulates are available on the market for the first time, and that the larger volumes in turn allow for lower prices. There are biocomposites available for a variety of applications, including consumer goods, toys, handles and shoes, façade and terrace elements, floors, automotive interiors and space applications.

COMPOSENS

The COMPOSENS project has, during the last 4 years, carried out research on biocomposite materials from flax, hemp and wood. This project responds to the growing demand from consumers and society to move towards more eco-friendly building materials, for example in the automotive sector. The research results of the COMPOSENS project will be unveiled at the closing event of the project, which will take place in September 2020 in Belgium.

Source : Compositeworld.com